Infrared temperature measurement window or infrared window (Infrared window) in the ultraviolet, visible light, infrared band has good permeability, is widely installed on the electrical cabinet shell, and power system of infrared thermal imager, thermometer and combined with the infrared guidelines for heating failure, through the infrared window can easily to electrical cabinet internal equipment of nondestructive testing, realize state maintenance. It is convenient for electric power monitoring personnel to find the hidden dangers of high voltage accidents, solve and maintain them in time, and prevent the occurrence of high voltage accidents. At the same time, the infrared window is also installed on a variety of high voltage switch cabinet, metal armored cabinet, city ring network cabinet and GIS high voltage equipment for internal temperature measurement observation. Eliminate the risk of causing high-voltage arc accidents during thermal imager inspection. Infrared window for the power plant 6KV and 400V fan, pump, coal mill, belt conveyor, and other motor junction box, 6KV switch cabinet, 10KV closed bus for infrared temperature measurement. Infrared window can also be on the transformer terminal box, switch box, cable separation box and other airtight equipment for infrared detection.

product model

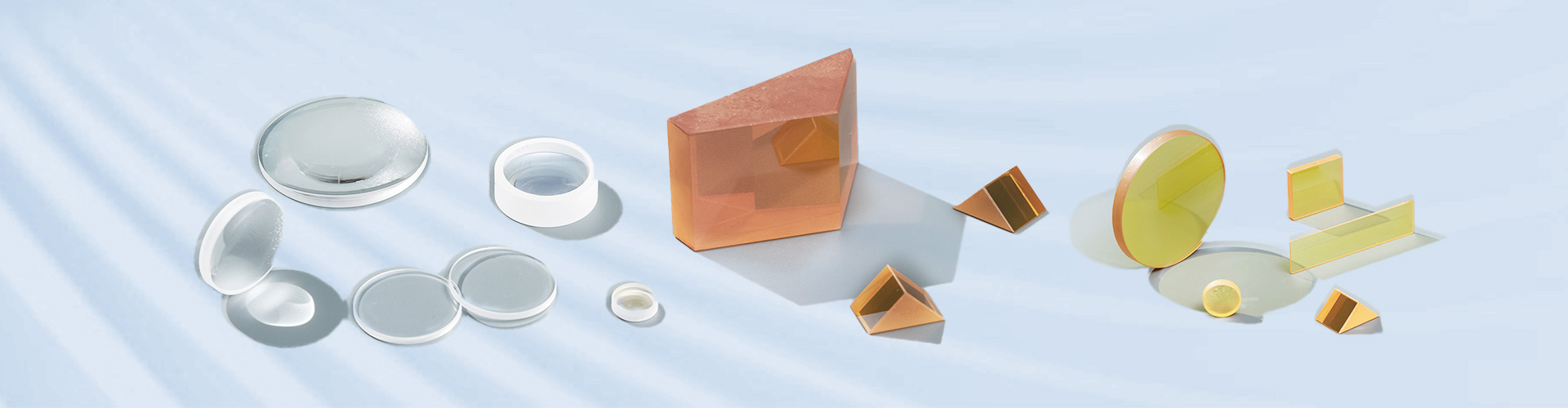

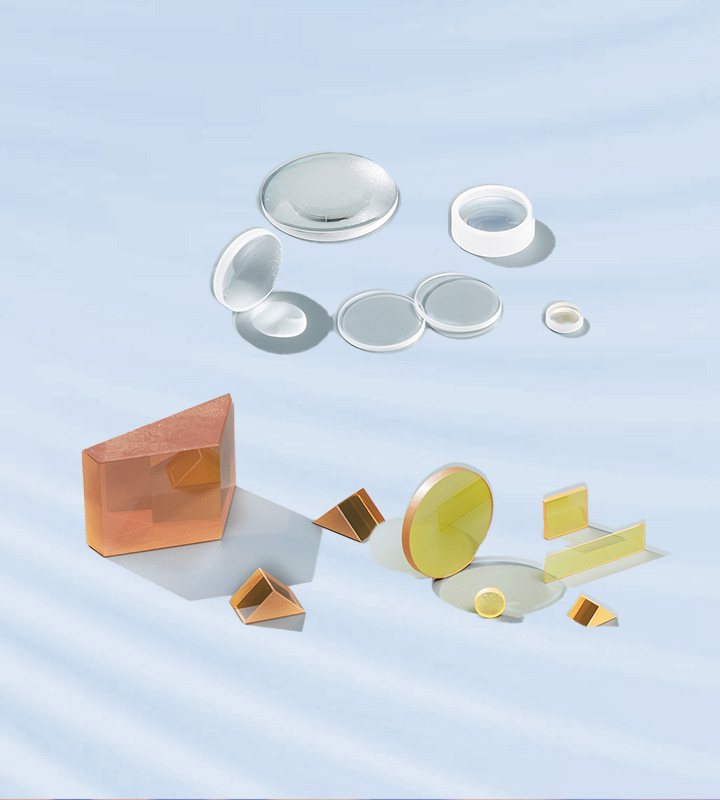

1. Material structure: aluminum alloy flange insert optical crystal material;

2. Working band: 0.15-14 microns, visible light, infrared ray, ultraviolet full spectrum;

3. Range of temperature measurement: -20°C- - + 500°C;

4. Working environment: the humidity is less than 90 degrees;

5. Installation method: vertical installation;

6. Protection level: IP44;

7. Flange protection cover thickness of> 2mm, detection can be adsorbed on the wall of the switch cabinet;

8. Fastening bolt nut; M5 * 8 stainless steel 304 hardness 12.9

9. Electromagnetic interference: none;

10. Melting point of the crystal material: 1,380 °C;

11. Crystal compressive strength: greater than 80 Newton / cm;

12. Observation mode: spin open the flange outer cover detection;

13. Field of view angle: 82° -125°;

|

model |

material quality |

transmissivity |

Short-time power-frequency withstand voltage test |

Window diameter |

Install the opening size |

life length |

|

WL-ITM-D60 |

Infrared composite crystal |

≥93%(0.15-14μm) |

15KV 1min |

60mm |

71mm |

More than 10 years |

|

WL-ITM-D75 |

Infrared composite crystal |

≥93%(0.15-14μm) |

15KV 1min |

75mm |

86mm |

More than 10 years |

|

WL-ITM-D80 |

Infrared composite crystal |

≥93%(0.15-14μm) |

15KV 1min |

80mm |

91mm |

More than 10 years |

|

WL-ITM-D88 |

Infrared composite crystal |

≥93%(0.15-14μm) |

15KV 1min |

88mm |

97mm |

More than 10 years |

|

WL-ITM-D100 |

Infrared composite crystal |

≥93%(0.15-14μm) |

15KV 1min |

100mm |

111mm |

More than 10 years |

Mobile website

Mobile website